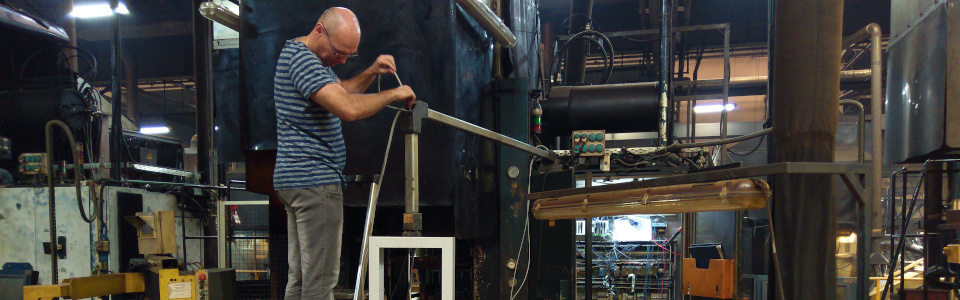

We simply renovate and repair injection molding machines and compression machines

Thanks to our independence and flexibility, we offer a wide range of services - from repairs, replacements of control systems to complete reconstructions of used old and new injection molding machines.

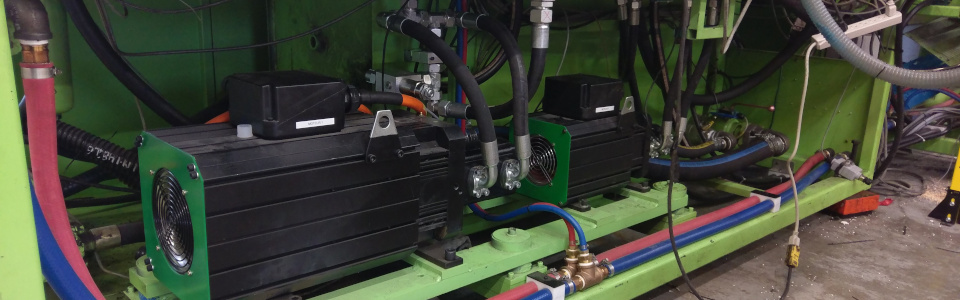

We exchange and install new control systems

We replace defective, obsolete and non-compliant control systems of all brands on all types of injection molding machines by Austrian systems Keba (www.keba.com).

We develope custom applications and user interface for all types of injection molding machines and compression machines. Our control has already been used on hundreds machines of several brands and types and is thoroughly tested in the automotive industry.

Togehter with our customers we always try to find the most cost effective solution before the exchange. This is possible mainly due to the independence of the machines manufacturer, which gives us sufficient flexibility and place for adjustemens.

We certainly pay attention to maintaining CE certificates.

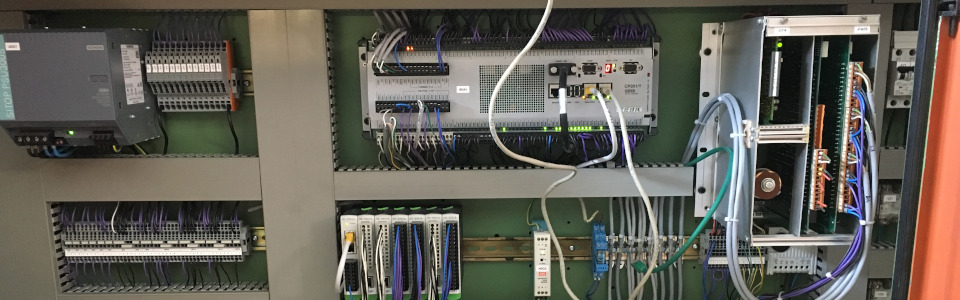

Moreover we program, update and extend applications on all injection machines with original Keba controller

We adjust application depends on the customer requirements or we implement completely new application which answer all customer expectations.

The machine can be also bought directly with the intention of new application implementation. This can compensate the main disadvantage of the low-cost machines. Such adjusted machines can be used also for the complex production in automotive after.

OPC Client for process data measurement and machine events monitoring

We implemented OPC client for machine events logging and unlimited process data collection into csv files. Logging and process data measurement are executed in real time through standard industrial OPC connection.

OPC client logs following machine events:

• alarms

• parameter changes

• infologs

• user login

• machine (production) status